The U.S. automobile heavyweight General Motors (GM) alongside the South Korean battery frontrunner LG Energy Solution has achieved significant progress in enhancing electric vehicles (EVs) with their new introduction of a lithium manganese-rich (LMR) prismatic battery.

Engineered for GM’s upcoming lineup of electric and full-sized SUVs, this innovative tech offers a remarkable 33% boost in energy density compared to the top LFP batteries currently available. This advancement provides increased power output without sacrificing affordability.

Thanks to this improvement in battery efficiency, GM’s forthcoming electric pickup trucks might exceed 400 miles per charge, which would be a notable achievement for extended-range electric vehicles.

The collaboration marks a major step forwards in battery innovation and solidifies the long-running partnership between the two companies, which plan to commercialize the LMR battery cells through their joint venue, Ultium Cells.

GM has announced that comprehensive manufacturing in the U.S. will commence in 2028, with preliminary stages anticipated to start by the end of 2027.

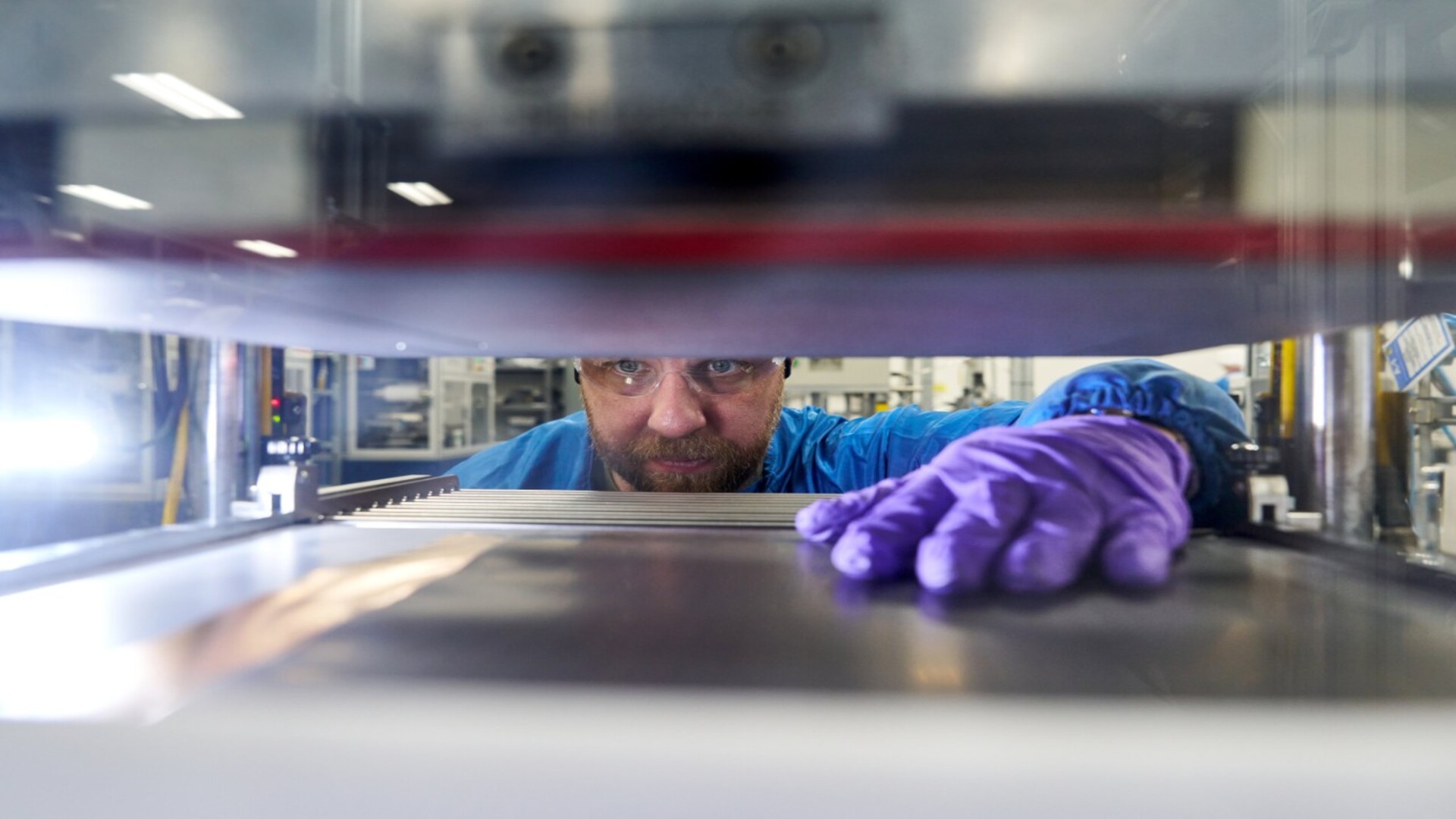

A cutting-edge electric vehicle battery design

In contrast to conventional cathode materials that depend significantly on expensive cobalt and nickel, LMR cells utilize a greater proportion of manganese, which is a more affordable metal. naturally abundant Moreover, it is considerably less expensive compared to rarer substitutes. This reduction in raw material expenses also facilitates higher energy density, which consequently supports extended ranges for electric vehicles.

GM indicates that using LMR prismatic cells provides a clear pathway for producing electric trucks capable of exceeding 400 miles of range, while simultaneously reducing battery pack expenses. Although the company’s present truck model already excels in this category through its use of high-nickel chemistry, incorporating these new cell types further enhances their potential. prismatic LMR cells has the potential to usher in a new epoch of electric utility vehicles.

Kurt Kelty, GM’s Vice President for batteries, propulsion, and sustainability, stated that this innovative technology aims to provide top-tier range and performance at a budget-friendly price point, specifically in electric trucks , where efficiency and value are crucial for broad acceptance.

"As we aim to develop the perfect battery for every vehicle within our extensive electric vehicle lineup, LMR will enhance our high-nickel and iron-phosphate options, thereby increasing customer choices in the pickup and full-size SUV segments, advancing American battery innovation “and generate employment opportunities for many years ahead,” Kelty asserted.

More than ten years in the making

Wonhoon Suh, LG Energy Solution’s Vice President and leader of the advanced automotive battery division, stated that the introduction of LMR prismatic cells marks several years of engineering advancements and innovations.

"GM's upcoming trucks driven by this new technology strongly illustrate our collective dedication to providing various electric vehicle choices to customers," he ended his statement. press statement , with the addition that this product showcases the company’s enduring dedication to improving battery tech in collaboration with GM.

Since 2015, GM has been working on LMR battery tech, and their Wallace Battery Cell Innovation Center in Warren, Michigan, has played a crucial part in improving the chemistry behind these batteries.

In order to address past issues related to the resilience and efficiency of LMR systems, GM’s engineering team has improved all facets of the battery cells. This includes enhancements to cathode materials, electrolytes, additives, as well as changes in assembly techniques.

The ultimate production-ready version of the battery will undergo validation at the firm’s forthcoming Battery Cell Development Center in Warren, anticipated to launch in 2027, along with LG Energy Solution’s facilities.

After validation, it will be incorporated directly into GM’s North American battery supply chain, thereby enhancing local manufacturing and material procurement support.

Posting Komentar

Posting Komentar