A novel method for energizing electric vehicles

If you believe that Detroit-based car manufacturers lag behind in providing electric vehicles (EVs), think again. General Motors is presently at the forefront, offering the Cadillac Celestiq , Cadillac Escalade IQ , Cadillac Lyriq , Cadillac Lyriq-V , Cadillac Optiq , Cadillac Vistiq , Chevrolet Blazer EV , Chevrolet Equinox EV , Chevrolet Silverado EV , GMC Hummer EV Pickup , GMC Hummer EV SUV , and GMC Sierra EV All of these are powered by electrons rather than petroleum.

General Motors and LG Energy Solution are collaborating to develop lithium manganese-rich prismatic battery cells, known as LMRs, which they intend to incorporate into upcoming GM models. General Motors aims to become the pioneer among automotive manufacturers by employing these LMR batteries starting from 2028. This innovative battery technology promises an increase of up to 30% in energy density compared with present-day equivalents but at costs comparable to those associated with today’s widely used lithium iron phosphate batteries, also referred to as LFPs.

We're thrilled to present the inaugural LMR prismatic batteries designed specifically for electric vehicles," stated Wonjoon Suh, who serves as the executive vice-president and leads the Advanced Automotive Battery division at LG Energy Solution. "These innovative cells will power GM's upcoming lineup of electric trucks, showcasing our collective dedication.

Following a comparable statement from Charles Poon, who leads Electrified Propulsion Engineering at Ford and spoke on April 23rd, came this new announcement. "We aren’t merely conducting experiments in a laboratory setting; we’re making efforts to expand the use of LMR cell chemistry with plans for integration into our upcoming models before the end of the decade."

Poon highlighted the reduced manufacturing expenses, increased power capacity, improved stability, and heightened safety of LMR batteries as primary reasons for their superior performance. Initially, Ford launched their electric vehicles equipped with NCM batteries but expanded their options in 2023 by incorporating LFP battery technology.

How LMR batteries differ

To grasp the differences between these batteries and those presently in use, one needs to comprehend how a battery functions. In essence, electricity is generated within a battery through reactions involving both the anode, which generates electrons, and the cathode, which consumes them. The electrolyte facilitates the movement of electrical charges between the anode and the cathode, resulting in the production of electricity as their combined output.

GM’s Ultium platform presently utilizes nickel-manganese-cobalt-aluminum-oxide batteries, commonly referred to as NCMs, featuring a cathode composition of 85% nickel, 5% cobalt, and 10% manganese. Nonetheless, both cobalt and nickel come at high costs, and cobalt extraction involves significant ethical issues due to instances of child labor exploitation. An alternative common battery type is lithium iron phosphate, or LFP, which is approximately 20% cheaper compared to NCM batteries; however, Chinese manufacturers dominate nearly all production of these cells, based on information from S&P Global.

On the contrary, LMR batteries utilize approximately 35% nickel, 65% manganese, and almost negligible amounts of cobalt. Since manganese is the fifth most abundant element on Earth and easily accessible, it ends up costing significantly less compared to both nickel and cobalt. The production expenses for LMR batteries are nearly identical to those for LFP batteries; however, they offer about 33% higher energy density. GM intends to manufacture prismatic-shaped cells instead of the current pouch-style ones, improving packing effectiveness and potentially cutting down component count by around 75%. Furthermore, this chemical composition performs effectively with larger cell dimensions, further decreasing overall system costs.

Although the Chevrolet Silverado EV Work Truck with Maximum Range boasts an EPA-estimated range of 492 miles, it employs an NCM battery. Opting for an LFP battery could enable GM to achieve comparable mileage while reducing costs, making the current starting price of $57,095 upgradable all the way to $97,895.

Final thoughts

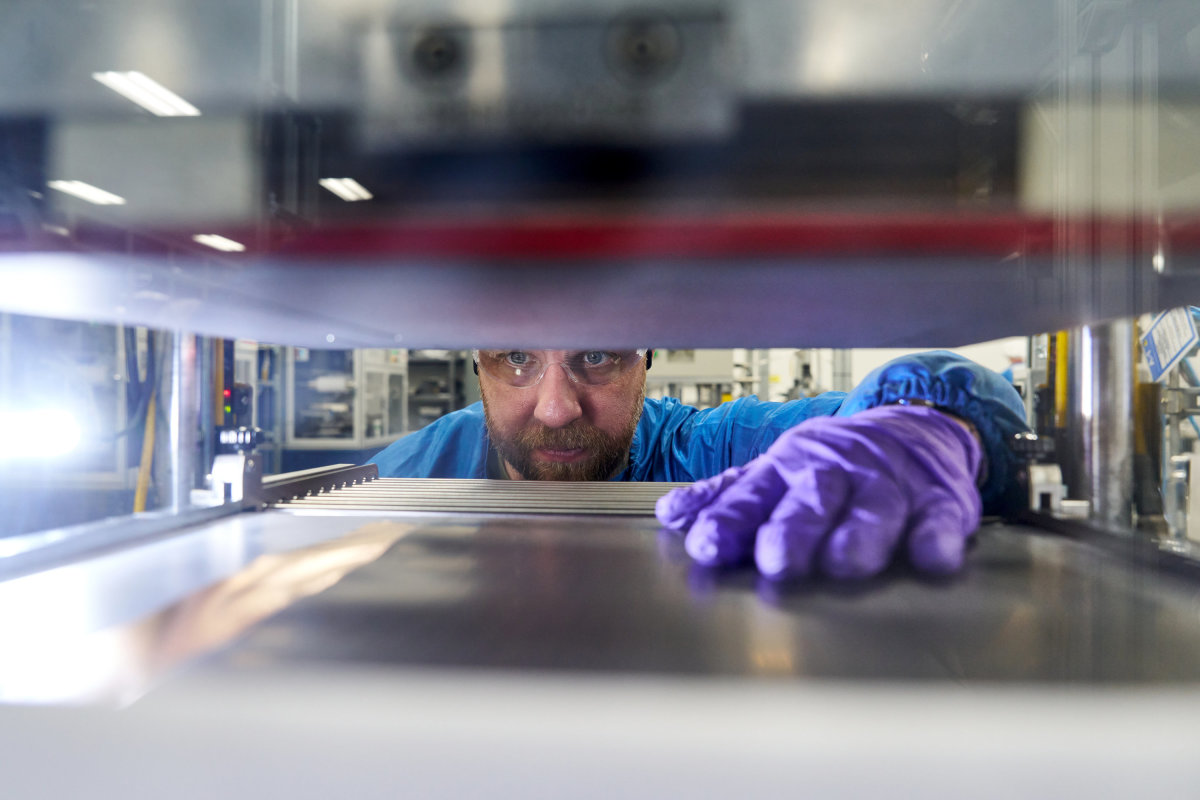

Although General Motors initiated investigations into manganese-based lithium-ion batteries as early as 2015, their performance and longevity did not meet expectations. These batteries typically had limited lifespans and rapidly lost charge over time. However, both GM and LG Energy Solution claim to have resolved these issues through "incorporating specialized additives and protective layers, alongside advancements in particle design and manufacturing processes." This approach aims to optimize the energy density and organization of components within each cell for enhanced stability, based on information provided in an official GM statement. Their collaborative efforts at the Wallace Battery Cell Innovation Center located in Warren, Michigan, have resulted in securing more than 200 global patents associated with this type of high-manganese-content chemistry.

In the end, GM believes this technology will offer greater range at a reduced expense, potentially lowering the overall cost of electric vehicles—a key barrier to their broader adoption. As per Cox Automotive data from March 2025, the typical amount spent on a new vehicle stood at $47,462. In contrast, the average expenditure for an electric car reached $59,205—marking a 22% increase over conventional cars and representing one of the highest premiums observed recently. These pricing dynamics are fueling efforts to decrease battery expenses, alongside trade policies encouraging manufacturers to lessen dependency on Chinese sources for raw materials and parts.

Posting Komentar

Posting Komentar